PRODUCTS THAT DELIVER

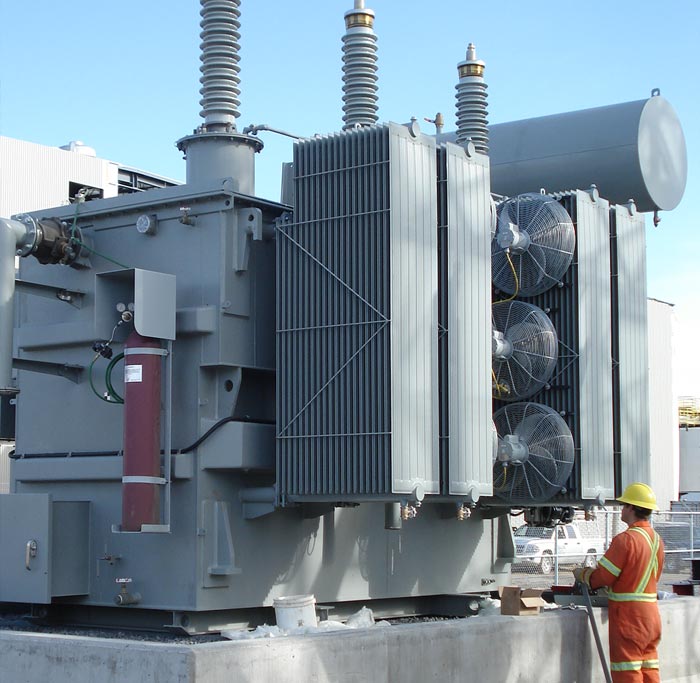

Our durable transformers deliver outstanding quality and reliability to boost the productivity and efficiency of your operations. Our expertise is in highly specialized power transformer applications:

- Three-phase transformers

- Single-phase transformers

- Autotransformers

- Isolation transformers

- Zigzag grounding transformers

Our line of liquid-filled power transformers is rated up to 150 MVA and 245 kV.

MARKETS AND APPLICATIONS

- Power production

- Industry

- Transmission and distribution

- Paper mills

- Cement plants

- Mining operations

- Petroleum gas: refineries, pipelines, etc.

- Coastal/offshore environments

MADE TO MEASURE

Our power transformers are designed to meet customers’ specific needs and requirements. Looking for a transformer with custom options and features? Our teams are ready to put their know- how to work for you.

CORES

Only the best materials go into our transformer cores. We use high-grade grain-oriented steel for superior quality parts that exceed technical standards.

WINDINGS

Custom windings allow us to ensure optimal transformer configuration. We carefully select the best conductors and insulating materials and use a disc-coil design to guarantee quality and reliability.

TANKS

Our transformer tanks meet the highest quality standards. The steel tanks are X-ray tested and welded by certified CWB professionals, then coated with a paint specially designed to withstand extreme weather conditions.

CONTROL PANELS

Ultra-sophisticated transformer controls allow you to monitor and adjust operation with a high degree of precision.

REPAIR SERVICE

Transmag Energy provides complete onsite equipment setup and repair services. We also have a mobile oil treatment and vacuum filling unit with a capacity of 5,000 liters per hour.

REFUBISHMENT

Transmag Energy now specializes remanufacturing polemounted and oil filled distribution transformer! Thanks to the establishment of our new factory on the south shore of Quebec, we are now able to produce up to 2000 units per year!

ONSITE SERVICE

When it comes to installation, maintenance, and emergency situations, our team of specialists is ready to respond onsite at any time. And if the situation requires specific expertise in electrical systems, we’ll call in the specialists at Gemitech for reinforcement.

DIAGNOSTICS

- Insulating oil analysis

- Dielectric loss measurement

- Sweep frequency response analysis (SFRA)

- External partial discharge detection

- Leakage reactance measurement

- Winding resistance measurement

- Transformer voltage ratio measurement

- Tap changer checks

- Accessory checks

- Visual inspections

- Control, command, and protection component checks

- Infrared thermographic inspections

ULTRAMODERN COMPLEX

With the support of cutting-edge techno- logy, our experts work in an ultramodern environment equipped with the most sophisticated tools, machinery, equipment, and testing instruments in the industry.

TEST LABORATORY

Our engineering department makes available to our customers a test laboratory equipped with the latest technology.

- Impulse voltage generator (BIL)

- Sound intensity and/or pressure measurement

- Dielectric (hipot) test stations

- Extreme high precision loss measurement system

- Modular variable voltage and frequency electronic test sources for induced voltage, no-load, and load testing

- Instrumentation for measuring partial discharge

- Capacitance and dielectric loss factor measurement

- Sweep frequency response analysis (SFRA)

- Winding resistance measurement

- Transformer voltage ratio measurement

TRANSFORMER OIL

PURIFICATION SYSTEM

In the same way a blood test can provide a doctor with a wealth of information about their patient, taking an oil sample enables service engineers to learn a great deal about the condition of a transformer.

Present and future transformer ratings require high quality and high purity insulating oils at the point of use. The increasing voltage and rating of the modern transformer and electrical apparatus results in greater electrical stress in insulating material and fluids. To handle these greater stresses, oils with better dielectric qualities are required. Also lower residual water content in insulating fluids and material must be maintained. The proper treatment and upgrading of the insulating fluid will result in the improvement of the properties of the entire insulating media of power transformers. The principal functions of the insulating fluid are to serve as a dielectric material and as an effective coolant. To perform these functions, the insulating fluid must have the necessary qualities at the time of initial impregnation and filling at the factory and later maintain the same quality in the field operation. Gemitech’s High Vacuum Process upgrades the new or used electrical insulating fluids including transformer oils, polybutenes and silicone fluids.

Gemitech’s (transformer oil purifier) high vacuum process is used for the dehydration and degasification of electrical insulating liquids including transformer oils, polybutene and silicone fluids, to increase and maintain their dielectric strength. The processing includes the removal of free and soluble water, dissolved air and gases and particulate matter.

Gemitech uses the ENERVAC degasser of 1200 gallons / hour and 65 KW of heating.

FULLER’S EARTH FILTRATION

Gémitech is continuing its investments with the acquisition of a new fuller’s earth filtration system to increase the performance of its oil treatment unit!

This next-level oil filtration system absorbs acids, gums / glues, resins and other active soluble contaminants that may end up in your equipment.

Another improved solution that we are adding to our service offering to regenerate your oil in an optimal and ecological way while significantly increasing the life of your equipment, protecting your investments at the same time!