Gemitech specializes in industrial electrical systems engineering. With extensive experience in the field, our team is recognized today as one of the industry’s most efficient. We can provide an accurate assessment of the state of existing facilities or facilities planned as part of large-scale projects. Using advanced calculation tools, our specialists draw up detailed plans based on precise studies and analyses.

ENGINEERING SERVICES

Our skilled engineers draw on a wealth of experience in a range of industrial projects to provide clients with sound advice.

- Prefeasibility and technical-economic feasibility studies

- Technical audits

- Profitability analyses

- Master plans

- Facilities modernization and upgrade programs

SPECIALIZED STUDIES

Gemitech can provide an accurate assessment of the state of existing facilities or facilities planned as part of large-scale projects. Using advanced calculation tools, our specialists complete comprehensive studies and analyses to draw up detailed plans.

- Integration with public utilities

- Protection coordination

- Short-circuit

- Arc flash hazards

- Power flow

- Network stability

- Harmonics

- Reactive compensation

- Power quality

- Motor startup

- Voltage drops

- Flickering

- Grounding, step and touch voltage

- Equipment failure analysis

- Utilities standards compliance

- Electrical Transient Absorber (Arc Suppressors) Sizing, Fabrication, Installation and Test Studies

DESIGN

Gemitech delivers turnkey solutions, from project design to completion. Our services are tailored to meet the specific needs of our customers.

- Plan and specification preparation

- Electrical substation design

- Overhead and underground power line design

- Grounding system design

- Protective relay setting and programming

- Maintenance programs

- Equipment upgrades

- Worksite supervision

- Electrical Transient Damper (Arc Suppressors) Installation for Power and Potential Transformers

Our engineering department provides customers with access to a state-of-the-art testing laboratory.

COMMISSIONING AND MAINTENANCE

Over the years, Gemitech has acquired unique expertise in commissioning large-scale projects, mostly in Quebec but also elsewhere in North America and in Europe. When it comes to low, medium, and high voltage substations, we have the experience and equipment to meet your needs. Our testing procedures meet IEEE, CSA, IEC, and NETA standards as well as all customer requirements.

Hydroelectric power stations and wind farms are two types of energy developments in which we excel.

EQUIPMENT TESTS AND MEASUREMENTS

- Liquid-filled power transformers

- Dry type transformers

- Low, medium, and high voltage circuit breakers

- Voltage and current transformers

- Low, medium, and high voltages witches

- Surge arresters

- Bushings and insulators

- Protection relays

- Instruments

- Cables (fault location, partial discharges, dielectric losses, tan delta)

- Grounding (continuity, step and touch voltage)

- Capacitors

- Inductance

- Motor control center

- Starters

- Motors

- Generators

TRANSFORMER OIL

PURIFICATION SYSTEM

In the same way a blood test can provide a doctor with a wealth of information about their patient, taking an oil sample enables service engineers to learn a great deal about the condition of a transformer.

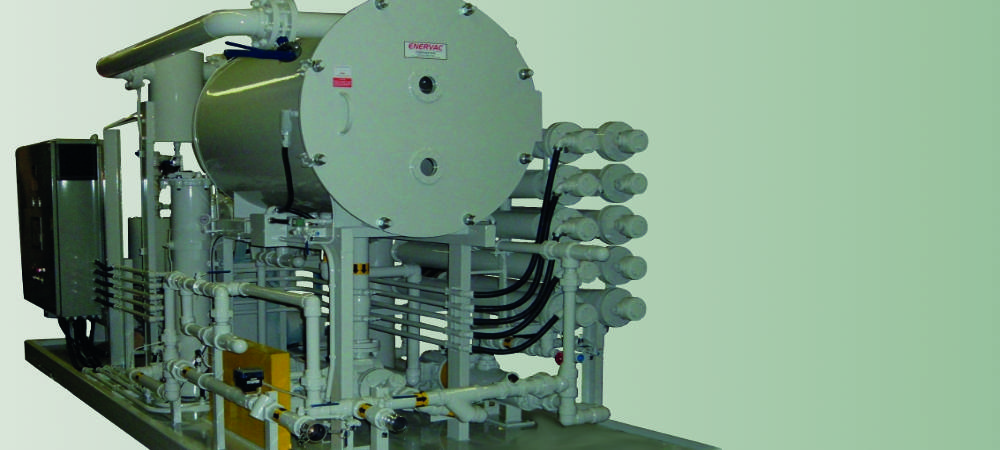

Present and future transformer ratings require high quality and high purity insulating oils at the point of use. The increasing voltage and rating of the modern transformer and electrical apparatus results in greater electrical stress in insulating material and fluids. To handle these greater stresses, oils with better dielectric qualities are required. Also lower residual water content in insulating fluids and material must be maintained. The proper treatment and upgrading of the insulating fluid will result in the improvement of the properties of the entire insulating media of power transformers. The principal functions of the insulating fluid are to serve as a dielectric material and as an effective coolant. To perform these functions, the insulating fluid must have the necessary qualities at the time of initial impregnation and filling at the factory and later maintain the same quality in the field operation. Gemitech’s High Vacuum Process upgrades the new or used electrical insulating fluids including transformer oils, polybutenes and silicone fluids.

Gemitech’s (transformer oil purifier) high vacuum process is used for the dehydration and degasification of electrical insulating liquids including transformer oils, polybutene and silicone fluids, to increase and maintain their dielectric strength. The processing includes the removal of free and soluble water, dissolved air and gases and particulate matter.

Gemitech uses the ENERVAC degasser of 1200 gallons / hour and 65 KW of heating.

FULLER’S EARTH

FILTRATION

Gémitech is continuing its investments with the acquisition of a new fuller’s earth filtration system to increase the performance of its oil treatment unit!

This next-level oil filtration system absorbs acids, gums / glues, resins and other active soluble contaminants that may end up in your equipment.

Another improved solution that we are adding to our service offering to regenerate your oil in an optimal and ecological way while significantly increasing the life of your equipment, protecting your investments at the same time!